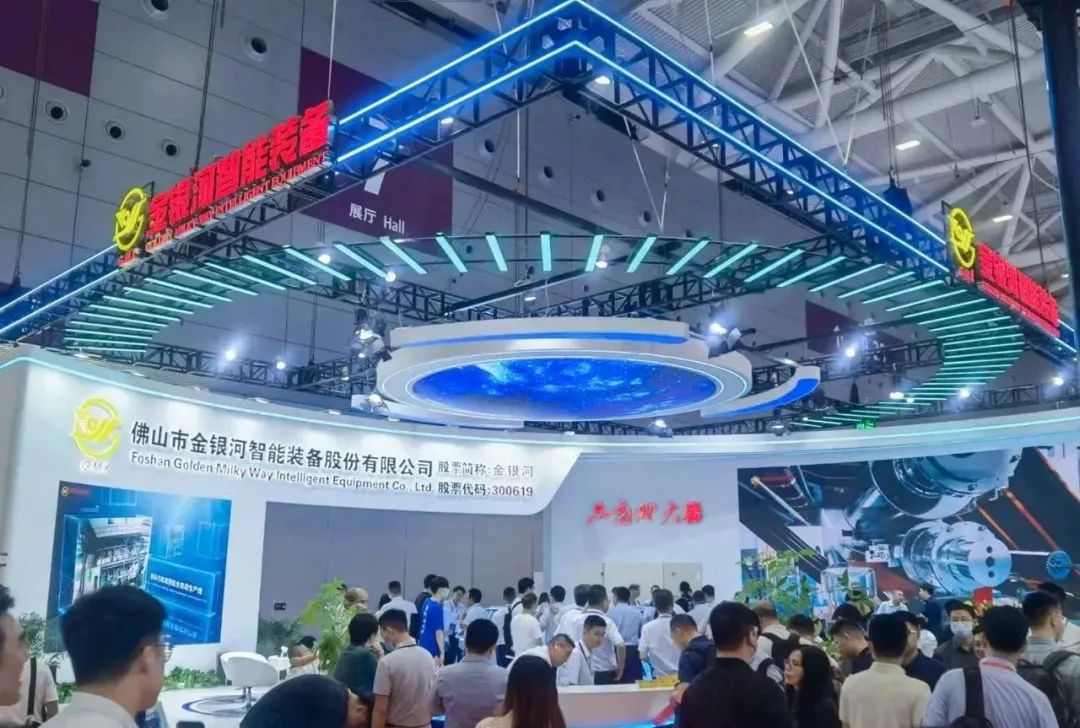

On May 16th, CIBF, the largest exhibition and technology exchange meeting in the international battery industry, was grandly opened at the Shenzhen Convention and Exhibition Center in China! GMK had sent a strong technical and sales team for this exhibition, providing customers with efficient and high-quality services.

GMK’ lithium battery positive and negative electrode intelligent manufacturing solution has realized one-stop manufacturing of the electrode, and opened a new chapter in the high-efficiency, energy-saving and green manufacturing of lithium battery electrodes. During the exhibition, GMK displayed the "GMK 3.0" series of lithium battery positive and negative poles slurry twin-screw continuous automatic production lines, the "Red Golden Dragon" series of double-sided wide-format high-speed extrusion coating machines, "Baoyueshan" three-roller series double-stage roller splitting machine, which is a complete set of equipment.

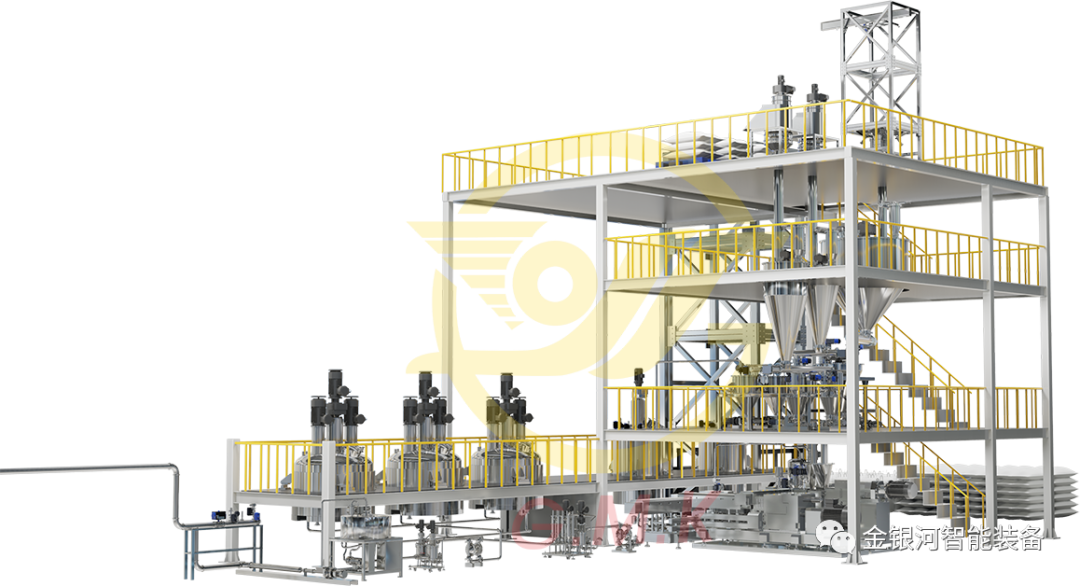

GMK3.0 series lithium battery slurry twin-screw continuous automatic production line, including powder metering and conveying system, liquid metering and conveying system, twin-screw screw mixing system, slurry storage and conveying system, DCS central control system. The forced continuous mixing and dispersion of slurry in a narrow space is realized, and the number of mixing can reach 80,000 to 120,000 times, forming slurry at an extremely fast speed. High production efficiency, up to 600-4500L/h slurry, realizing production capacity of 1-10 GWH; high degree of automation, low labor intensity, saving manpower; compared with traditional mixing production, it can save about several million to tens of millions of kilowatt-hours of electricity a year , saving energy consumption; the slurry produced has good dispersion and mixing effect, high solid content, stable viscosity, and is suitable for large-scale lithium battery slurry production.

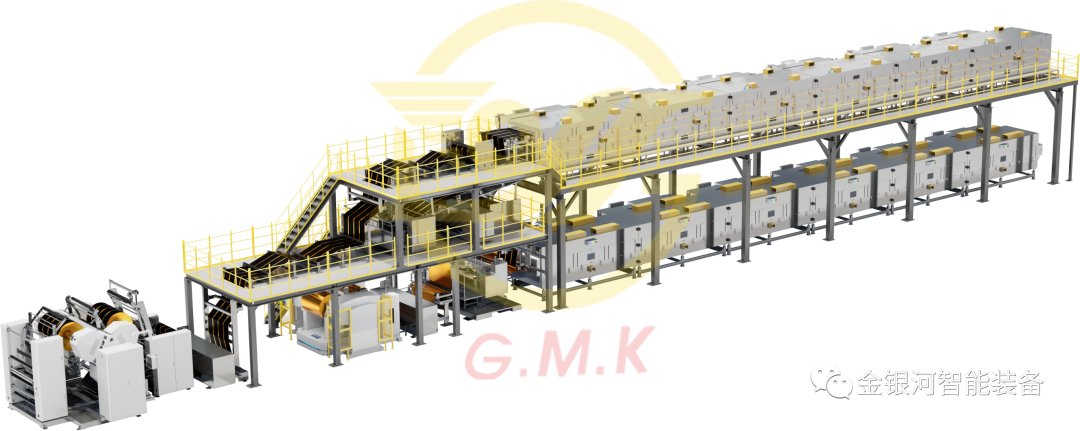

"Red Golden Dragon" series wide-format double-sides extrusion coating machine is a high-speed, high-efficiency, high-precision, and highly intelligent equipment. It is mainly composed of winding and unwinding, machine head, traction and oven. The oven adopts a special inner winding reversing design. Compared with the same type of coating machine, the number of operators remains the same, and the operation of the pole piece in the oven is more stable. The pole piece drying quality is higher, the coating production capacity is at least doubled, and the energy consumption is only about 1.7 times. In addition, using GMK's original three-axis automatic rewinding and unwinding transfer device, the coating machine and the roll-press slitting machine can be connected into a coating-roller-splitting machine, which does not interfere with each other during production and reduces conventional coating. The pole piece transfer work between winding and rolling unwinding can effectively improve production efficiency.

"Baoyueshan" three-roller series two-stage roller splitting machine integrates the functions of high-precision two-stage roller press and slitting machine. Compared with the traditional double-machine continuous rolling method, it can save 50% of the floor area and production cost, and the installed power can be reduced by more than 100KW; the rolling mode can be switched flexibly, and the rolling main machine can quickly switch between single and double rolling according to needs; The storage and stretching device in the pressing room can solve the problem of stretching after one rolling, and can also solve the problem of extending and storing the pole piece between two rollings; the unique independent knife feeding device, the speed of each cutting knife It can be adjusted separately, which can realize the simultaneous cutting of material and foil, and overcome the industry problem of copper and aluminum powder sticking to the foil when cutting separately.